Laser Induced Incandescence (LII) |

|

TheoryLaser-induced incandescence (LII) measurements is an emerging technology that offers a reliable means for spatially and temporally measuring the soot volume fraction and primary soot particle size in engine exhausts. The LII is a real-time measurement technique that can be used for in-situ measurement of particulate emission in engine exhausts. The instrument can also be used with sampling lines. With the LII, the soot within the laser beam path is heated rapidly using a pulsed laser source with duration typically less than 20ns. The soot is heated from the local ambient soot temperature to a temperature approximately equal to the soot vaporization or more accurately, sublimation temperature (approximately 4000 to 4500 K). The incandescence from the soot particles is measured using collection optics and photodetectors. With appropriate calibration and analysis of the incandescence signal, information on the soot volume fraction and primary soot particle size may be obtained. Laser energy absorption by the soot particles and the subsequent cooling processes involve complex analysis of the nano-scale heat and mass transfer in time and space. The method is largely non-intrusive and is capable of making in situ measurements over a very large range of soot concentrations in both flames and under ambient conditions. However, it is not completely non-perturbing as the laser heating can be expected to affect the soot morphology. ApplicationsThe LII 200 has been tested quite thoroughly over the past year and the fundamental capabilities demonstrated under a variety of applications including carbon black monitoring and process control, diesel engine exhaust emission and vehicular on-board road tests. Typical results are presented below for a carbon black manufacturing process control application (Fig. 1) and soot emission measurement in a diesel engine exhaust (Fig. 2).

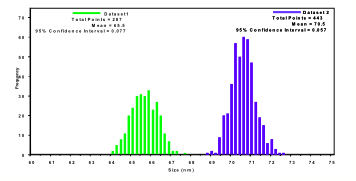

Figure 1: Carbon black primary particle size measurements under two different manufacturing process conditions.

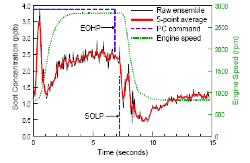

Figure 2: Diesel engine soot concentration vs engine speed.

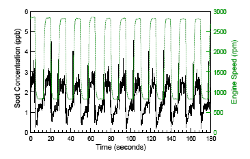

We have also conducted on-board road testing of the LII 200 unit in collaboration with Chevron, NRC Canada, and Sandia National Labs. The on-board measurement of time-resolved particulate matter (PM) emissions is a highly desired but elusive capability needed for investigation of real-world emissions. For this study, the LII 200 instrument and ancillary equipment were installed in the trunk and fold-down back seat area of a 2002 Volkswagen Jetta with a 1.9 liter TDI diesel engine with common rail injection. The LII 200 instrument dimensions are 50x58x13 cm, with ancillary equipment consisting of a mini-tower PC and flat-screen monitor, laser power supply, ejector pump and compressor to extract exhaust from the tailpipe through a sampling tube clamped to the tailpipe, and an 18 amp gasoline generator. The generator dimensions are 51x38x33 cm, and the laser power supply is comparable in size to the PC. All of the equipment was easily fit into the Jetta. An OBD-II scan tool interface was used to access the vehicle and engine speeds for recording by a dedicated notebook PC as the vehicle is driven around several loop routes in the vicinity of the Sandia National Laboratories California site in the Livermore Valley. These measurements were time-matched with the LII measurements to obtain a synchronized data set correlating time-resolved PM emissions with vehicle operating conditions that will include accelerations from a stop, hill climbing, and freeway driving. Typical results are presented in Figs. 3 & 4.

Figure 3: Soot volume data obtained while driving the VW along I-580.

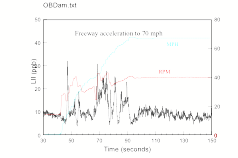

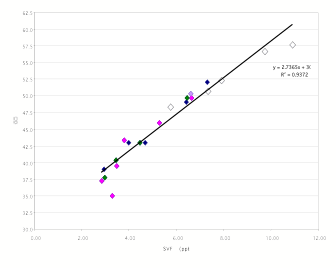

Figure 4: Soot volume fraction as a function of freeway acceleration. Tests were also recently conducted in the exhaust of a Pratt & Whitney Auxiliary Power Unit (APU) gas turbine engine, model PW980A SN SN4814B4. For each Data Series the exhaust sample gas control valve was indexed to send the exhaust sample to the Pratt and Whitney instrumentation. Gas analysis measurements were acquired followed by three filter paper particulate collections. The reflectance of the particulate sample was measured and converted to a Smoke Number Reading. After the Pratt and Whitney measurements were completed the gas control valve was indexed to send the exhaust sample to the Artium LII200. A comparison of the soot volume fraction and the smoke number is presented in Fig. 5.

Figure 5: Comparison of the SVF and smoke number in a gas turbine engine exhaust.

|